Grease Salt Spray Corrosion Tester

60L salt fog test cabinet supplier/salt spray test machine/salt spray test equipment

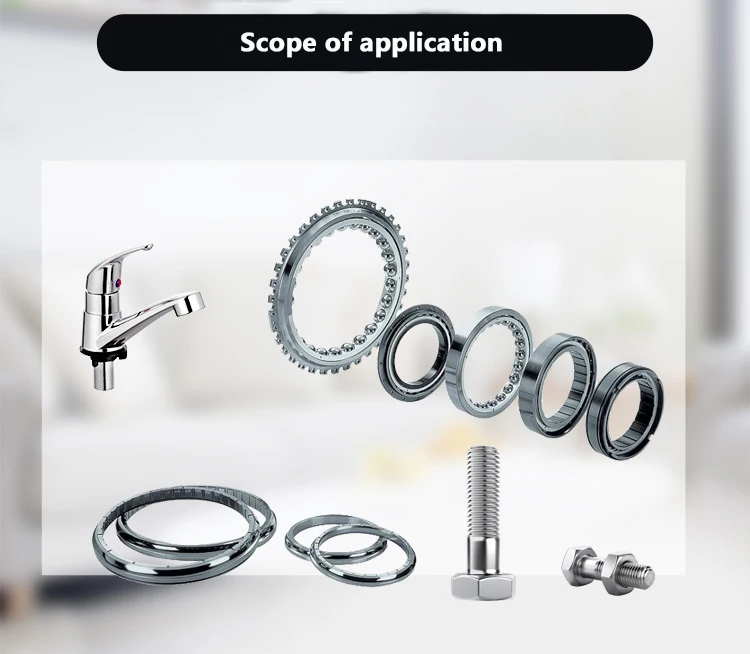

use

The salt spray test machine is used for the surface treatment of various materials, including coatings, electroplating, organic and inorganic coatings, anodizing, anti-rust oil and other anti-corrosion treatments, and testing the corrosion resistance of the products.

Materials used:

a laboratory uses P.V.C polyvinyl chloride board, acid and alkali resistant, easy to clean. (Germany (Yallis)

b The test chamber sealing cover is made of transparent impact-resistant acrylic sheet. (Germany NSP)

c reagent supplement bottle with hidden low water level indicator light, easy to clean, not easy to break

d saturated air tank with SUS#304 stainless steel high pressure bucket insulation effect is best

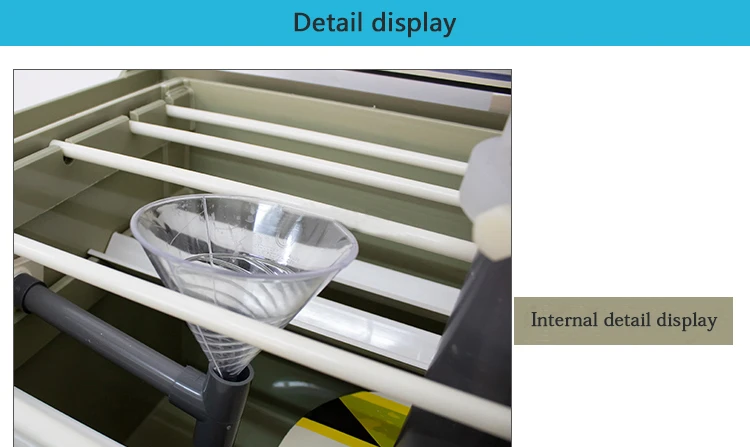

e laboratory blue frame mining plane indexing frame, according to the standard requirements of 20 ° ± 5 ° angle, four sides of the fog and fog are completely consistent, the number of test pieces placed

Spray system:

a using the Bernotte principle to absorb salt water and then atomize, the degree of atomization is uniform, and the phenomenon of non-blocking crystallization can ensure the standard of continuous testing.

b nozzle: made of special glass, can adjust the amount of spray and the angle of spray

c spray amount: adjustable 1-2ml (80cm2 / hr) (16 hours average)

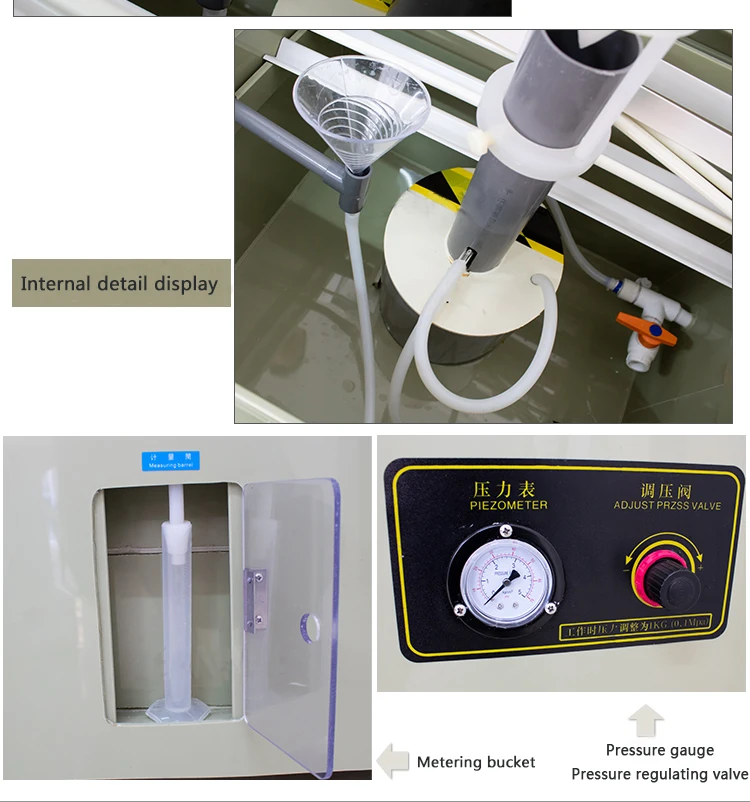

Air supply system:

The air pressure is 1Kg/cm2 in two-stage adjustment.

The first section is to adjust the 2-2.5 Kg/cm2 import type and has the function of filtering oil and water.

The second paragraph is a precision adjustment 1Kg/cm2 1/4PT pressure gauge.

Control System:

With the company’s independent research and development control system, it can recover tens of thousands of hours of trouble-free operation in a harsh working environment. Integrate all current test methods (including continuous, interval).

Standard accessories

1 type shelf

2 storage stick

3 standard measuring cylinder

4 temperature indicator pin

5 filter (please replace it regularly)

6 fog collector 80cm2

7 tempered glass nozzle (replaced after 5000H)

8 defogging system

3.Specification parameter list of salt spray test machine:

| Model | HY-60 | HY-90 | HY-120 | HY-160 | HY-200 |

| Inner box size: | 60*45*40 | 90*60*50 | 120*100*50 | 160*100*50 | 200*100*50 |

| (L×W×H) cm | |||||

| Outside box size: | 108*108*65 | 135*112*75 | 190*128*125 | 230*128*125 | 270*128*125 |

| (L×W×H)cm | |||||

| Temperature range | 35℃~55℃; | ||||

| Test chamber temperature | NSS ACSS 35℃±1℃(CASS 50℃±1℃) | ||||

| Saturated air barrel temperature | NSS ACSS 47℃±1℃(CASS 63℃±1℃) | ||||

| Temperature fluctuations | ≤±0.5°C | ||||

| Temperature uniformity | ≤±2.0°C | ||||

| Lab volume | 110L | 270L | 600L | 800L | 1000L |

| Brine tank capacity | 15L | 25L | 40L | 65L | 80L |

| Multiple safety protection devices | Water shortage; over temperature ;phase protection | ||||

| Standard accessories | Test salt, measure bucket, tool etc 1 set | ||||

| weight (kg) | 60 | 90 | 180 | 280 | 450 |

| Power | AC220V 1Φ20A | AC220V 1Φ20A | AC220V 1Φ30A | AC220V 3Φ15A | AC220V 3Φ15A |

4.Picture analysis of salt spray testmachine

1. Are your company a trading one or a factory?

Factory ,13years focusing on test instruments field,3 years exporting experience.Our factory is in Dongguan, Guangdong, China

2. After an order is placed, when to deliver?

Usually about 15 working days, if we have finished products, we can arrange delivery within 3 working days.

Please note that our production lead time depends on the specific project and the number of projects.

3. What about the warranty with after – sales services?

12 months warranty.

After the warranty, the professional after-sales service team will provide comprehensive technical support to help customers solve problems encountered when using our products, and promptly handle customer problems and complaints.

4. What about the services and product’ quality?

Service: ,Design service,Buyer lable service.

Quality: Each instruments must be carried out 100% quality examination and test, the finished products must through a third party calibration institutions before shipping and delivery goods.